Healthcare Manufacturing Automation Solutions

MGS brings decades of experience in custom automation technologies for plastic component manufacturing, built on a strong foundation in complex injection molding technologies. As an early pioneer in multishot molding systems like injection units and rotary platens, we apply that expertise to develop automation solutions that support Pharma, Diagnostic and MedTech production.

By using our own manufacturing equipment alongside innovative technologies from strategic supply chain partners, we deliver scalable medical device manufacturing automation that drives ROI at every stage of the process. This ensures consistent manufacturing efficiency, less manual labor, integration flexibility and cost-effective operations and maintenance.

Scalable Medical Device Automation Technologies

At our Automation Technology Center in Germantown, WI, MGS creates a focused environment where our skilled engineers drive industry-leading automation innovation. This work happens on the same campus where manufacturing processes are designed, tested and brought to life. Dedicated to setting new standards every day, we specialize in building healthcare automation equipment primarily for plastics processing, including software and controls capability.

Cutting-Edge Custom Automation Solutions

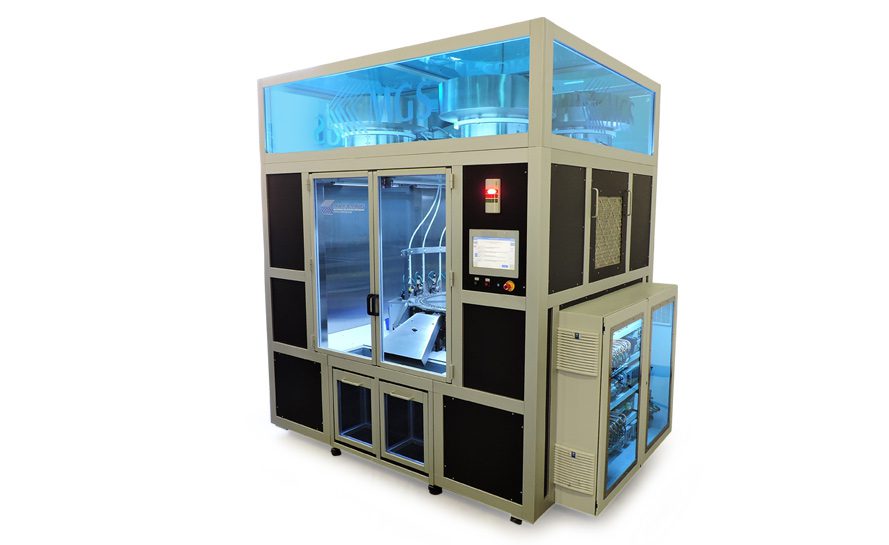

Our healthcare automation solutions range from simple, semi-automatic benchtop workstations to fully integrated press-side cells with downstream assembly and testing. Each system is designed to operate independently and produce a finished, packaged product.

In-House Healthcare Manufacturing Automation Solutions

With years of experience in Design for Manufacturability (DFM), we deliver deep expertise in healthcare manufacturing automation. Our systems are built to follow complex manufacturing processes and meet strict regulatory requirements.

Mechanical Engineering

Our robust solutions are built for serviceability and long-term performance. With nearly maintenance-free designs, we help maximize uptime and operational efficiency.

Electrical Engineering

We use advanced control hardware to simplify wiring, reduce connection points and make troubleshooting easier and faster.

Software Development

Our front-end software is intuitive and user-friendly, giving operators full control of the system while streamlining reporting and diagnostics.

All automation equipment meets Industry 4.0 standards and supports Euromap 77 and 83. Our design and fabrication processes also meet Class 8 cleanroom requirements.

Quality Control You Can Trust

Quality is the most critical function in any automated process. At MGS, we invest in training and equipment to conduct in-house feasibility studies before finalizing process specifications. Doing so gives our customers confidence that their medical device assembly automation solutions are fully validated, reliable and ready to perform as expected in their production environment.

Contact Us

Want to learn more about how our healthcare manufacturing automation solutions can help you reduce costs, increase speed and mitigate risk?