Elevating Product Quality with Advanced Manufacturing Solutions

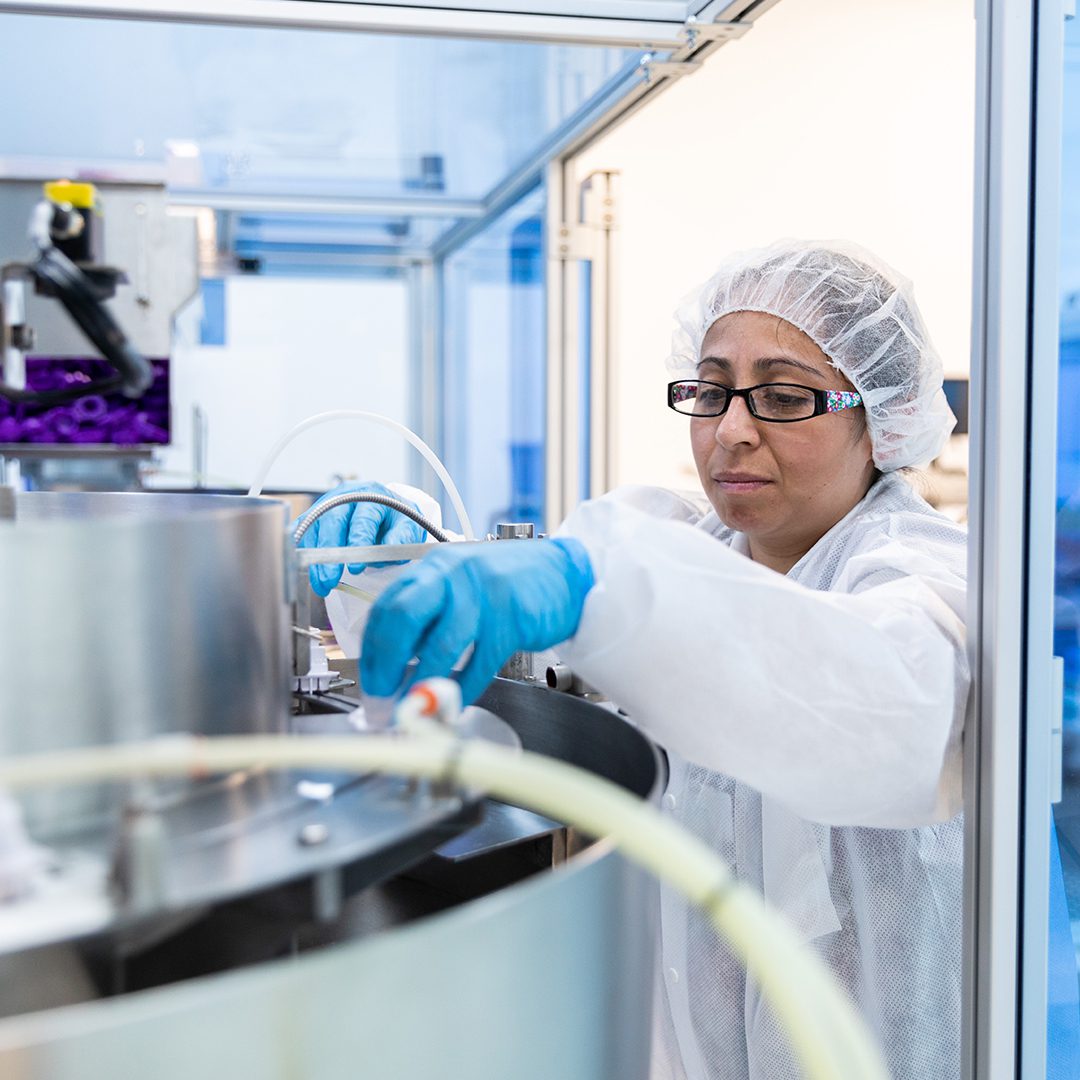

At MGS, we transform our customers’ most pressing challenges into life-improving innovations through state-of-the-art manufacturing. Our advanced Pharma, Diagnostic and MedTech manufacturing facility offers end-to-end solutions, including advanced injection molding, precision assembly and rigorous quality assurance. Designed to accelerate production cycles and enhance collaboration, our Germantown Manufacturing location is equipped to deliver the highest standards of excellence for customers across North America.

MGS Germantown features independent Class 8 cleanrooms totaling approximately 50,000 square feet. These cleanrooms currently house more than 80 injection molding machines and 12 cleanroom assembly cells. These production areas are supported by a leading-edge quality lab, a fully staffed tool shop for regular tool maintenance and repair, and a distribution center to help you manage your part and product deliveries based upon your unique needs.

MGS Germantown

N117 W19125 Fulton Drive

Germantown, Wisconsin, USA 53022

Phone: (262) 255-5790

Fax: (262) 255-7206

Located right next to MGS’ Innovation Center and Headquarters, MGS Germantown offers seamless integration with design, development and automation teams, enabling faster production cycles, enhanced collaboration and streamlined processes to deliver high-quality solutions efficiently.

Our Manufacturing Certifications

Our manufacturing facilities are certified to meet and exceed your exact specifications for quality and safety standards.

FDA Registration #: 3011179004