Avoiding Tooling Bottlenecks with Greater Capacity

Formerly Winther Mould Technology A/S, MGS Lynge is a full-service tooling facility with mold design, manufacturing, test and validation capabilities. Specifically focused on healthcare applications including drug delivery device contract manufacturing, diagnostics and other MedTech applications, subject matter experts at MGS Lynge work alongside customers and our global team to accelerate timelines. Our unparalleled capacity and expertise ensure customers can experience the highest levels of quality and best time to market with fully validated tooling solutions.

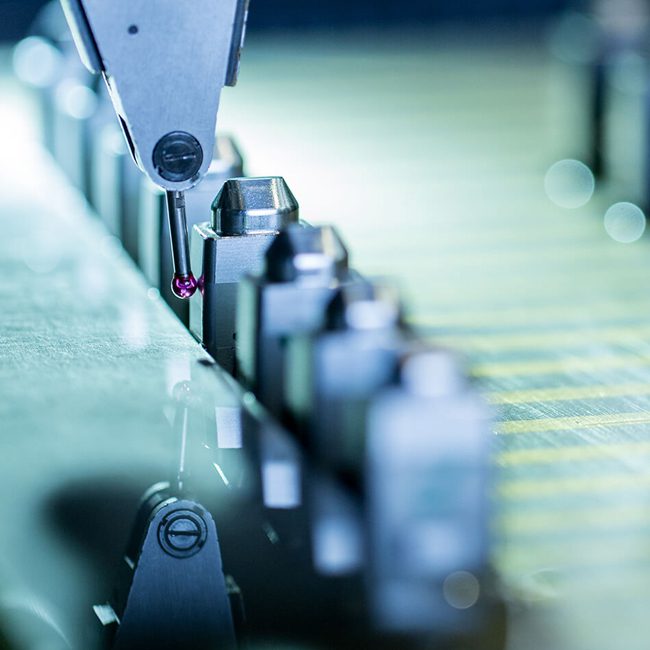

Within our 4,000-square-meter production floor, we deliver high-precision, high-complexity molds for the healthcare industry. We have the advanced manufacturing systems and processes in-house to support you from 3D printing to prototype molds to high-volume production molds. We recently renovated our facility to integrate the latest in mold development manufacturing technologies including 5-axis laser texturing, high-speed precision milling and automated robotic handling to accelerate quality and drive even greater efficiency closer to you.

Customers can also tap into our 3,000-square-meter test and validation center that provides space for full process validation and metrology without disrupting production. We have the flexibility to integrate processes for customers including First Off Tool (FOT), Design of Experiment (DOE), validation, transfer and pilot production. Customers can access injection molding machines ranging from 50-300 metric tons to perform complete mold and machine process validations.

Watch this short video to learn more about our recent expansion at MGS Lynge.

Centrally located and part of our Medical Design & Engineering hub in Denmark, individuals at MGS Lynge work closely with our European and global teams to deliver best-in-class CDMO medical solutions to our customers. We take pride in every tool that leaves our facility, leveraging strong DFM and ESI capabilities that set our customers up for success before, during and after launch.