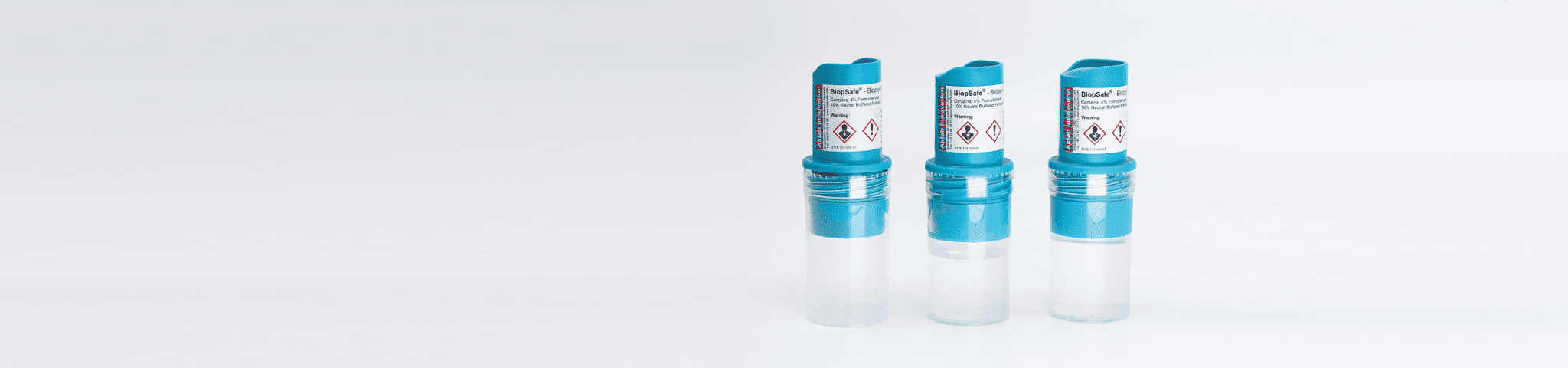

Knowing well that the most prominent risk of handling biopsies is the risk of exposure to formalin, Axlab wanted to enter the market as legal manufacturer by creating a simple device that would make it safer and faster for healthcare professionals to handle biopsies. Their first ever Medical Device.

View the final product to see how easy and simple and most of all safe handling of biopsies are now. Then find out what the CEO of Axlab has to say about the experience below.

Our task was clear:

- Create an intuitive Medical Device

- Have it ready for CE-marking

- Set up a complete Quality Management System for the company

- Make ordering new products as easy as pushing a button

The Lay Of The Land

Rising expectations to hospital efficiency and a growing focus on employee safety have fueled the ever increasing need for safer, easier and more efficient procedures for handling biopsies. In line with this reality Axlab wanted to create a new and better way of handling biopsies from retrieving the biopsy to analysis of the biopsy. Due to the lack of experience with medical device development they also wanted MGS Design & Development to help them set up a Quality Management System to ensure that the developed product would meet regulatory requirements and be CE marked.

Testimonials

What People Say?

Insights you might also be interested in:

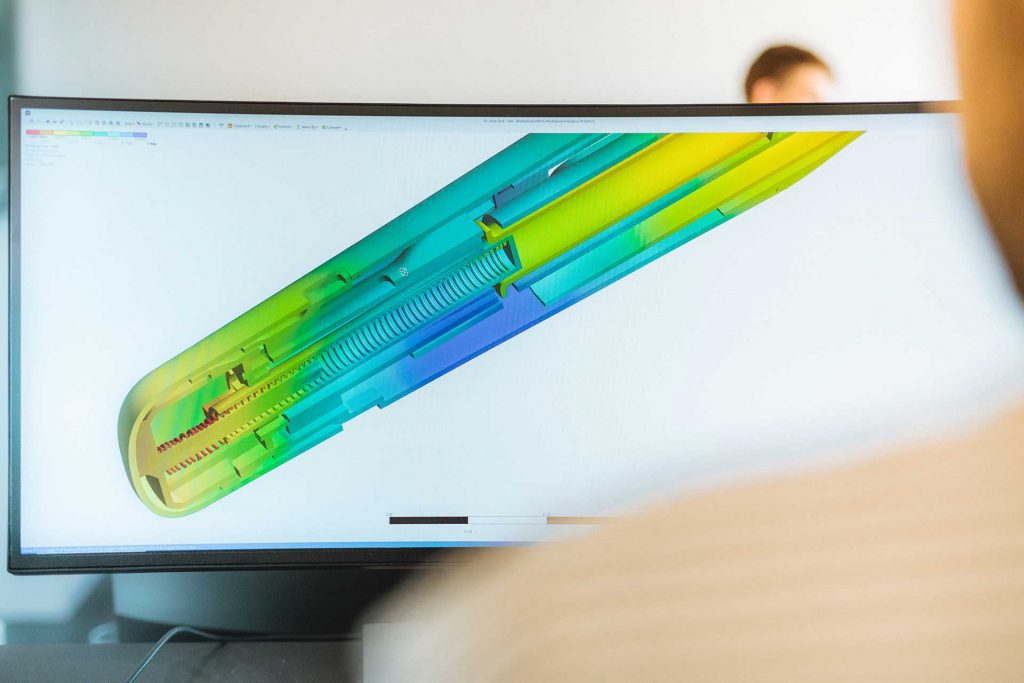

Why you Should Apply Virtual DoE to the Design Process

Will a medical device break apart when dropped onto a concrete floor? Does the device remain safe and functional if stored for years on a shelf before reaching the patient?

Regulating Medical Devices in the European Union: Legislation vs. Driving Business Outcomes

Healthtech magazine article shines the spotlight on the challenges and rewards of building your business processes around regulatory compliance.

How Early-Stage Drop Test Simulations Can Uncover Hidden Design Optimization Insights

Learn from ALK’s success with MGS Design & Development experts, gaining crucial insights for smoother testing and reduced project risks.