ScanClime® Humidity Control is a new platform used to regulate the ventilation and humidity of cages for laboratory animals, where animal welfare and climate control is a key parameter.

After producing the first prototype (proof of concept), Scanbur needed external expertise to define the platform, varieties, and structure, as well as to implement detailed product maturation and industrial design.

Scanbur wanted the new platform to strengthen their business base and market position through:

- Improved performance

- Modular product

- Offering multiple functions on the same platform

- Improved visual design and service access

MGS Design & Development has added resources and pace by implementing the following:

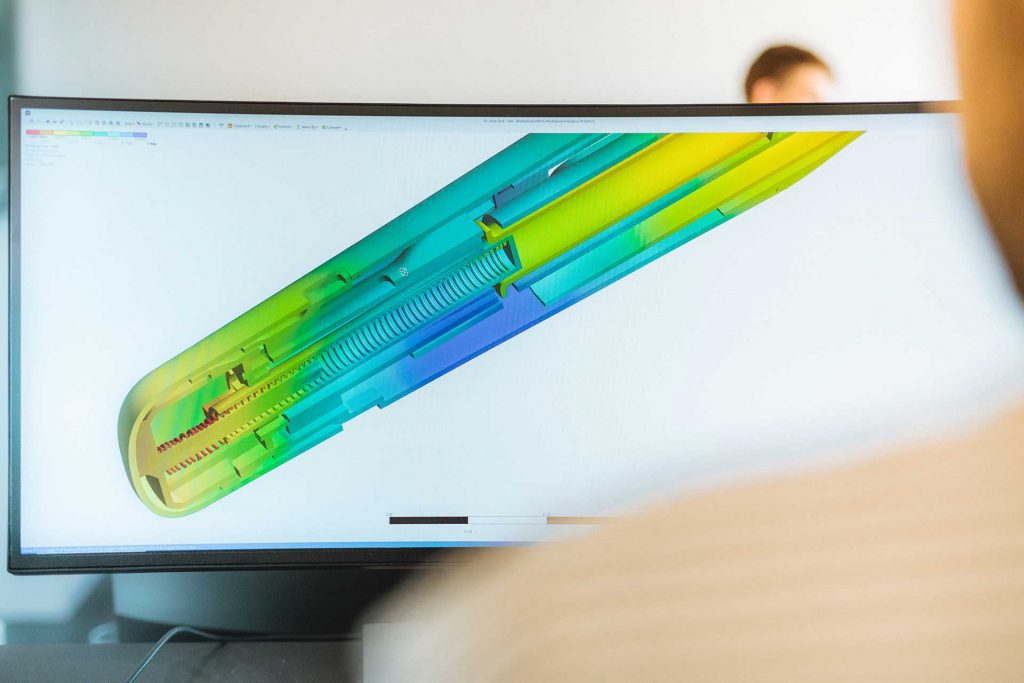

- Internal structure that conveys a robust, high-end product while meeting requirements for hygienic conditions and product construction

- Optimization of sub-functions

- Development of mechanical components, including injection and blow molds

- Supplier selection for central components

- 2D/3D documentation

- Optimization of product cost price through selection and optimization of components, simplified test and assembly processes (Simplimize)

- Cost price follow-up system

- Assistance with regulatory approval

- Identification of relevant standards

- Listing of essential components and acquisition of data

These activities were carried out in close collaboration with Scanbur employees.

Aside from assisting with the mechanical development of the product, MGS Design & Development has contributed with:

- Design identity that clearly signals the desired values and differentiates from competitors

- Development of a self-supporting chassis that adds a visual identity to the product

- Internal structure that optimizes the possibilities for variants (Simplimize):

- Multiple variants can be produced based on a single platform

- Large savings on components and assembly time achieved

- Selection of components that optimize function and reduce cost price (Simplimize)

- Overall, a new and competitive business platform for Scanbur, created through a broad program producible at very competitive prices

The article on MedWatch.dk supports this statement:

Denmark’s Scanbur has won its biggest contract ever to supply medical equipment worth millions to a new department at the Karolinska Institute – an order that strengthens the company’s confidence in its own product development.

Read the original article here: Karolinska injects millions in Danish medtech company.

Testimonials

What People Say?

Insights you might also be interested in:

Why you Should Apply Virtual DoE to the Design Process

Will a medical device break apart when dropped onto a concrete floor? Does the device remain safe and functional if stored for years on a shelf before reaching the patient?

Regulating Medical Devices in the European Union: Legislation vs. Driving Business Outcomes

Healthtech magazine article shines the spotlight on the challenges and rewards of building your business processes around regulatory compliance.

How Early-Stage Drop Test Simulations Can Uncover Hidden Design Optimization Insights

Learn from ALK’s success with MGS Design & Development experts, gaining crucial insights for smoother testing and reduced project risks.