Innovate Healthcare Products and Shorten Time-to-Market With Simulation & Modeling

Our Capabilities

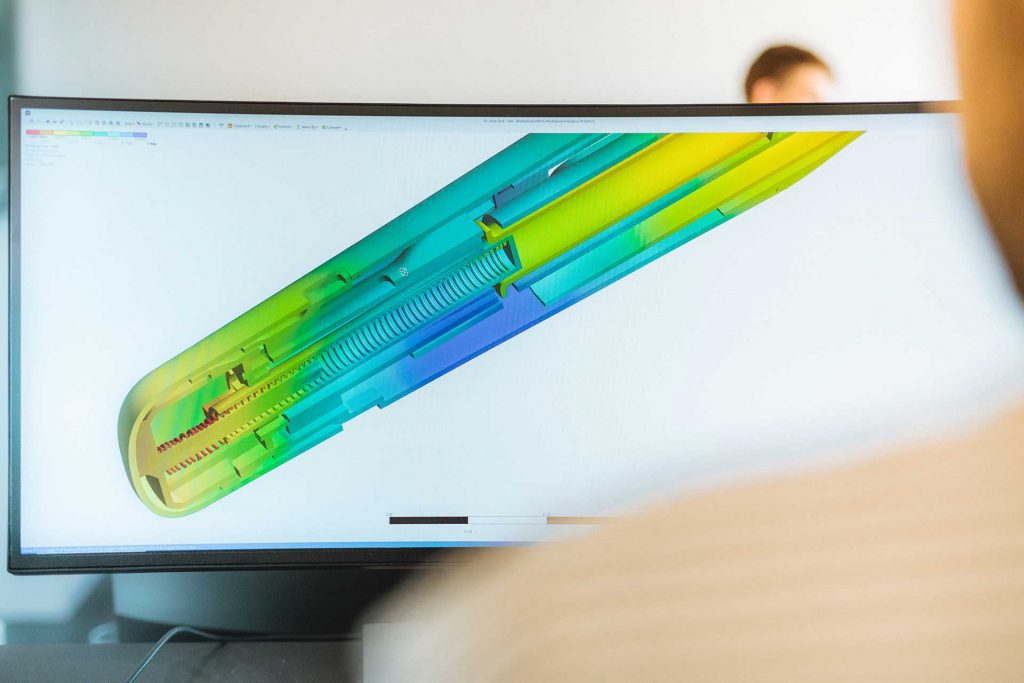

A multiple and varied set of disciplines are managed by our experienced team responsible for Simulation and Modeling:

Drop Testing

Variation Studies

Design Review – DFM & DFA

Assembly Simulations

Material Models

Model Validation

Shelf-Life Calculations

Functional Assessments

How Can Simulation & Modeling be Applied to Development of Devices?

Want to know more?

Get in Touch

Do you want to know more or didn’t you find what you were looking for? Reach out to our Simulation and Modeling team.

We Have the Expertise to Take You From A to Z

Whether you need a single competency or a combination of skills, our experts in Design & Development are ready to assist you through the entire process. Based on the specific needs of the project, we assemble the ideal team of specialists.

We are able to integrate advanced manufacturing knowledge into the earliest design phase and minimize the number of iterations. Our complete offering takes your project seamlessly through the entire value chain – From Imagination to Realization.

Check out all our areas of early-stage design expertise.

Related Cases

What are the Benefits of Simulation With the Finite Element Method?

Will a medical device break apart when dropped onto a concrete floor? Does the device remain safe and functional if stored for years on a shelf before reaching the patient?

Why you Should Apply Virtual DoE to the Design Process

Will a medical device break apart when dropped onto a concrete floor? Does the device remain safe and functional if stored for years on a shelf before reaching the patient?

How Early-Stage Drop Test Simulations Can Uncover Hidden Design Optimization Insights

Learn from ALK’s success with MGS Design & Development experts, gaining crucial insights for smoother testing and reduced project risks.